AM Machine (Additive Manufacturing)

.

One of Årdal Maskinering’s newest areas of investment within innovative and sustainable technology is additive manufacturing.

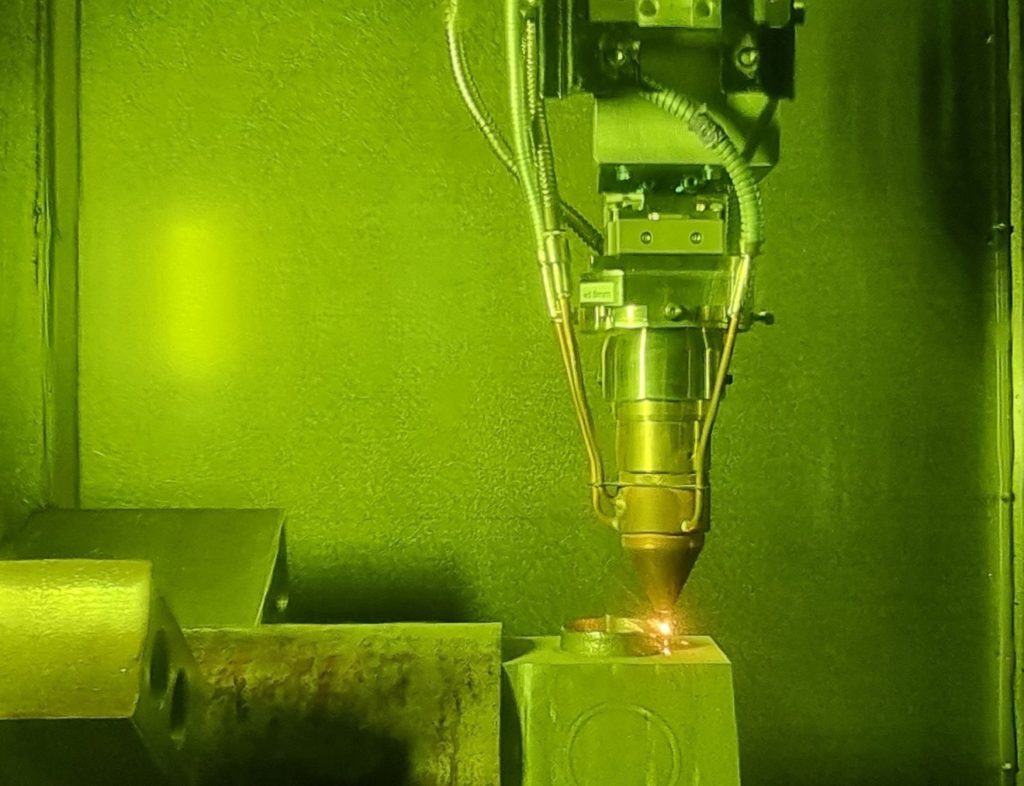

We have acquired a Mazak I500-AM. This is a 5-axis lathe with integrated AM function. AM is a description of a process that “adds material”. Multiple types of technology are included in this category: 3D printing and welding is among the most well-known processes. We use DED technology (Direct Energy Deposition).

This process consists of smelting on material in powder form via a powerful laser, where the type of laser used determines which material can be cladded.

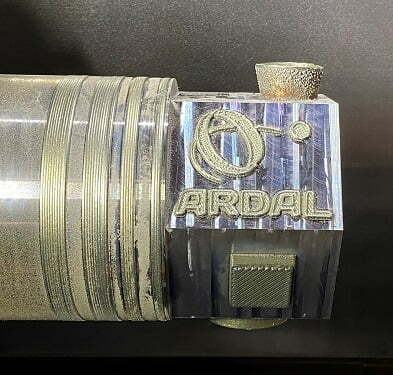

The significance of this is that we can construct an element on an existing part that does not need to be of the same material type.

The laser we use is suited for cladding materials such as stainless, Inconel or hard metal. This has no significance for which material the main component is made of.

The machine is also equipped with an infrared camera monitoring the smelting process of the powder material and adjusts the laser in real time to maintain correct values throughout the process.

The process is programmed via CAM system which makes it possible to create advanced geometries, and as the machine is also a 5-axis lathe, further machining of the cladded object will be carried out immediately without involving more machines.